18 Apr Emergency Repairs In A Sulfur Recovery Unit

Industry: Refining & Petrochemical

Description of Equipment: Sulfur Recovery Unit

Problem: Excessive hot spots were evident due to the failure of the current refractory lining and repairs were necessary.

Solution: Thermbond refractory was chosen to eliminate lengthy thermal dry-out time, and its ability to chemically bond to existing refractory materials. Thermbond Formula 18-G and 18-R were selected for their high purity and temperature rating.

Product Being Replaced: Conventional tabular alumina castable and tabular alumina firebrick

Savings Using Thermbond: The use of Thermbond Formula 18 series material eliminated the lengthy thermal dry-out time and the customer was able to save three days during the shutdown

Products Applied: Thermbond Formula 18-G, Formula 18-R

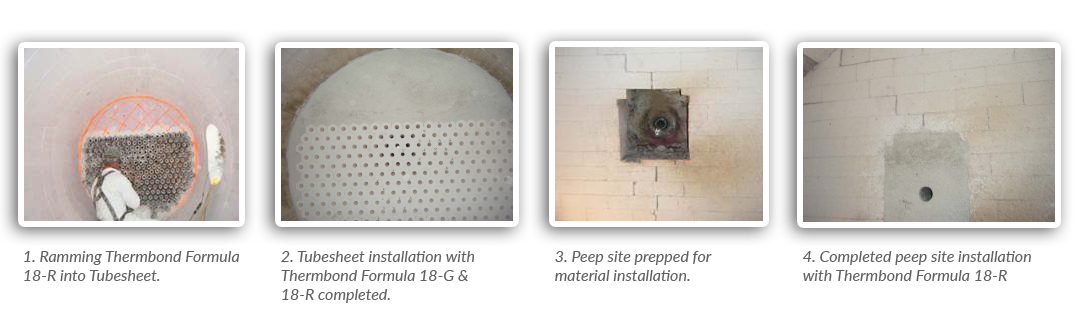

Method of Installation: Gunning, handpacked, and ramming

Equipment Used: Gunning equipment and mortar mixers

Scope of Work: SRU measured 8’ in diameter and 8’-10’ long. Removed failed brick, failed burners, and failed ceramic ferrules. Thermbond Formula 18-G was gunned around perimeter of tubesheet. Thermbond Formula 18-R was then rammed between each ferrule. Peep-site repair region required two to three 4” tall, V-Anchors around the new peep-site nozzle. After removal of the failed items, the contractor quickly repaired the areas and successfully restored heat to the unit within 48 hours.

Installation Date: November 2015

For additional information on this installation, please contact Industry Specialist Brendan Gallagher at [email protected].