23 Feb 7206 Installation

Industry: Secondary Power Industry

Description of Equipment: Unility Boiler

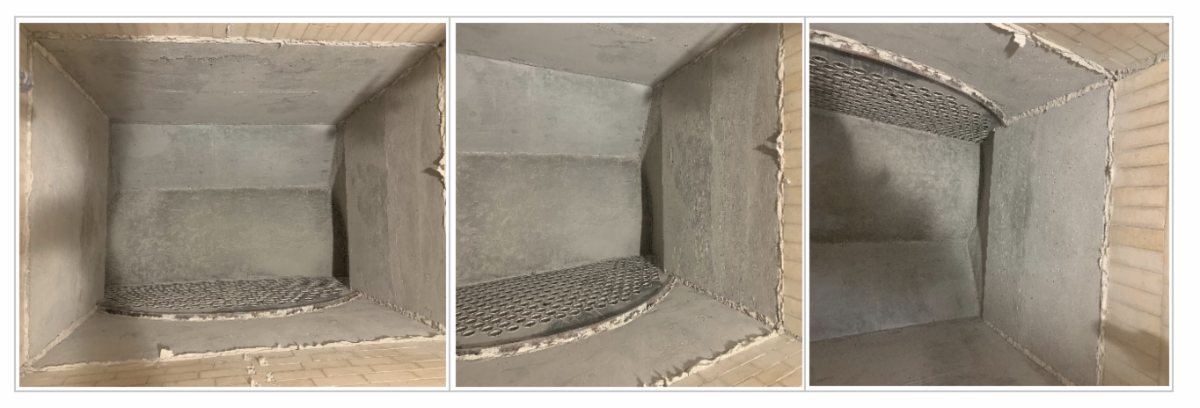

Problem: This was a new utility boiler that potentially required three different conventional refractory materials to cast, ram and gun. The problem was the installation method for specific parts of the boiler was difficult to determine until the actual installation started.

Solution: The contractor chose to use Thermbond 7206 because of its installation versatility.Thermbond 7206 can be cast, rammed or gunned by changing the liquid component used. Maximum installation versatility, all in one bag. In addition, the ability to do a fast heat-up eliminated the need for a third party dry-out company.

Product Being Replaced: Conventional Refractories

Results: The contractor had only great things to say about the 7206. The fact that only one material was needed for the entire installation was huge. The transition from the side wall to overhead was seamless. “One of the easiest and best working materials we have ever used” was the way the project manager described 7206. The start up went off with out any problems as well. 7206 saved them time and money. Since doing the boiler installation, the contractor has continued to purchase 7206 for many other jobs.

Products Applied: Thermbond 7206

Method of Installation: Cast and ramming

Equipment Used/Scope of Work: Barrel mixer, ramming tools, and pencil vibrator. Because 7206 is nearly a self flowing material, very little vibration was needed to move the product for casting. Working time for casting and ramming provided the contractor flexibility in executing the scope of work. Curing time even in November was shorter than conventional refractories.

Installation Date: November 2020

Follow Up: November 2021 for yearly inspection

Salesman involved: Brendan Gallagher