01 Nov Introducing Thermbolt

To reflect our new brand strategy, effective immediately, our STELBOLT Series will be renamed THERMBOLT®. The design of the product has not changed, simply the name. Continue reading for additional information about our THERMBOLT® (formerly STELBOLT) product line.

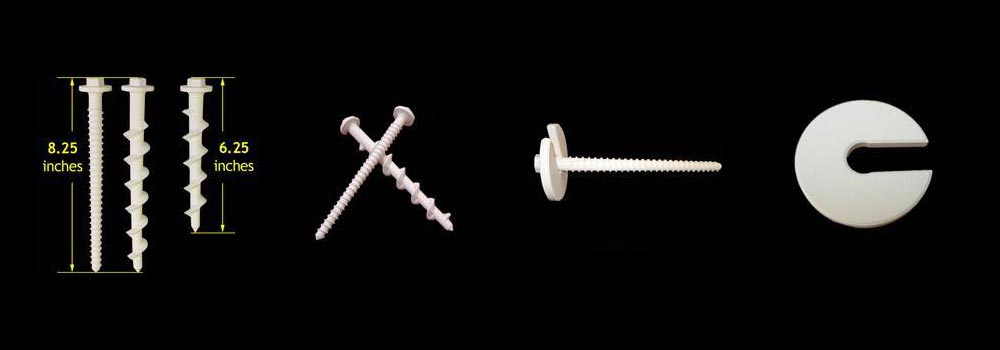

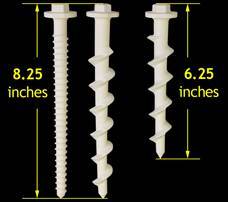

THERMBOLT® was designed to both repair and complement existing furnace linings. It can easily penetrate and hold onto a refractory fiber, insulating firebrick or light weight monolithic lining.

For repairs, a blanket patch can be placed over a damaged area where THERMBOLT® is drilled or ratchet driven through the new hot face and into the back up lining. THERMBOLT® will easily penetrate wallpaper, modules, and low density board linings. Bolts are typically applied at 1 per 1.5 sq. ft. on walls and 1 per 1.25 sq. ft. on roof areas. Burner openings, door areas, flues etc. are simply THERMBOLTED as required.

THERMBOLT WASHER – We have designed a washer for use with THERMBOLT® to provide additional bearing surface beyond the washer section of THERMBOLT®. The washer is a 3” diameter and has a .75 inch slit for ease of installation. Simply drill THERMBOLT® to within an inch or two from final depth, slide this washer onto THERMBOLT® and complete the installation.

THERMBOLT® washers increases the retaining area of THERMBOLT® by 3 times.

The THERMBOLT® series and THERMBOLT washer were designed to maximize furnace lining efficiencies through the use of MAFTEC™ ® hi alumina fiber blanket. MAFTEC™ ® blanket is rated to 3000°F with 1% shrinkage to 2600°F. The MAFTEC™ ®/THERMBOLT® combination compliments ceramic fiber linings by taking the brunt of the heat and substantially reducing those open joints in 2600 modules, that do nothing but cause downtime and energy loss. MAFTEC™ ® allows higher firing capability of your existing lining without extensive lining deterioration.