Simply Unrivaled

Insulating Solutions

Simply Unrivaled

WHAT ARE THERMBOND

INSULATING SOLUTIONS?

WHAT ARE THERMBOND

INSULATING SOLUTIONS?

Thermbond Insulating Solutions are engineered and customized systems for long-term or cyclic high-temperature environments. Many Thermbond Insulating Solutions use MAFTEC™ a world-class PCF that has superior insulating characteristics, unrivaled thermal stability and unparalleled health & safety properties.

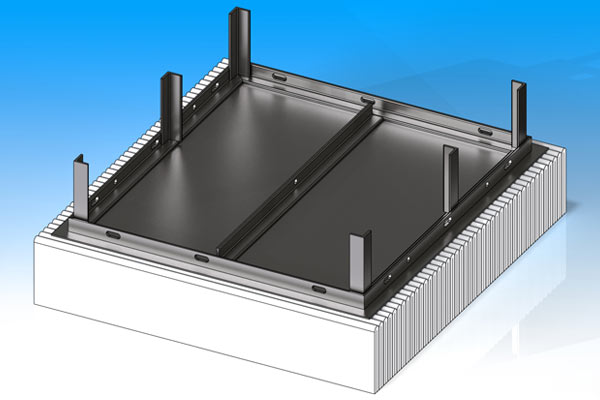

Ladle Cover

Furnace Door

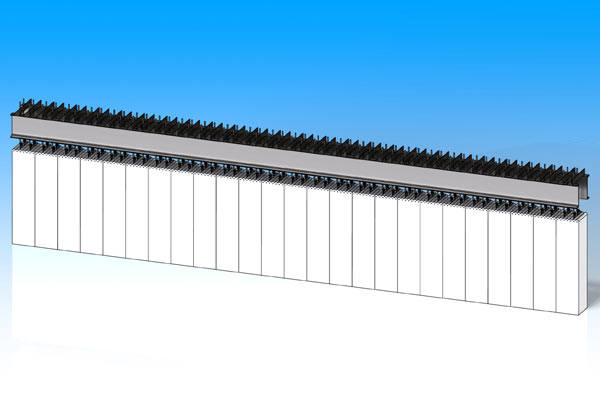

Hanging Curtain

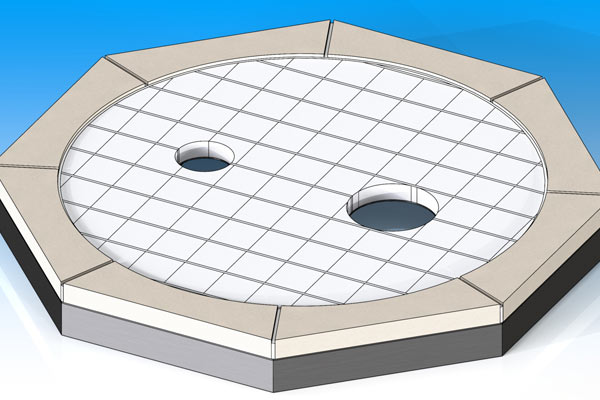

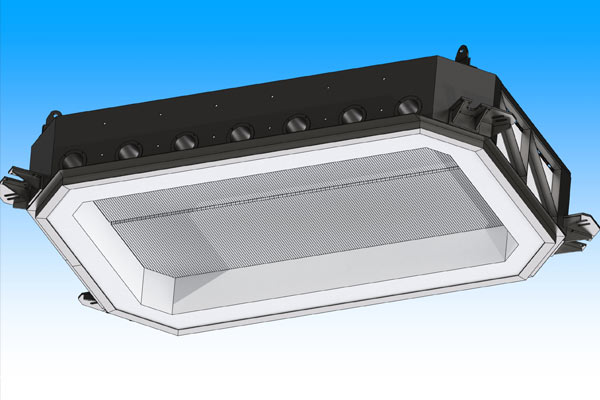

Filter Box Lid (top)

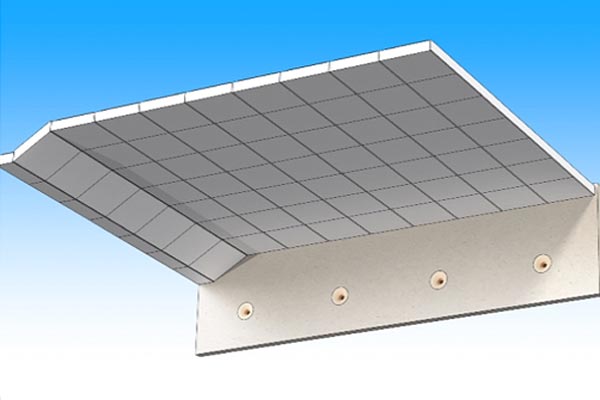

Thermbond Insulating Solutions PCF Lined Roof

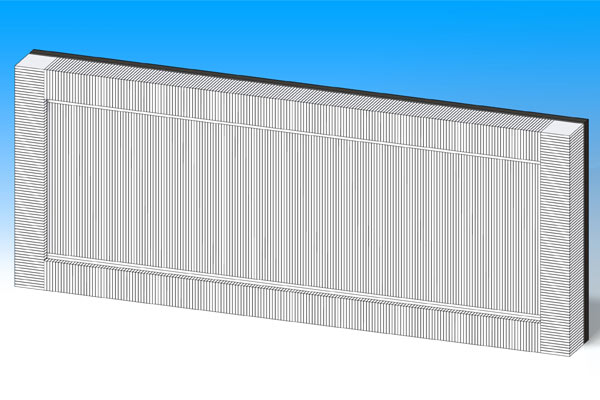

Panel

A BENEFIT FOR NEARLY EVERY INDUSTRY

A BENEFIT FOR NEARLY EVERY INDUSTRY

Thermbond Insulating Solutions have become the long-lasting, high-temperature solution of choice for a variety of industries. Providing excellent insulating properties and durable nature translates into significant energy savings for a wide range of industrial processes. The reduction in fuel consumption improves a firm’s bottom line, while creating a smaller carbon footprint in the process. Thermbond Insulating Solutions save time & money for professionals in the following industries:

ALUMINUM

METAL FORGING

STEEL

HYDROCARBON PROCESSING

POWER GENERATION

MINERALS PROCSSING

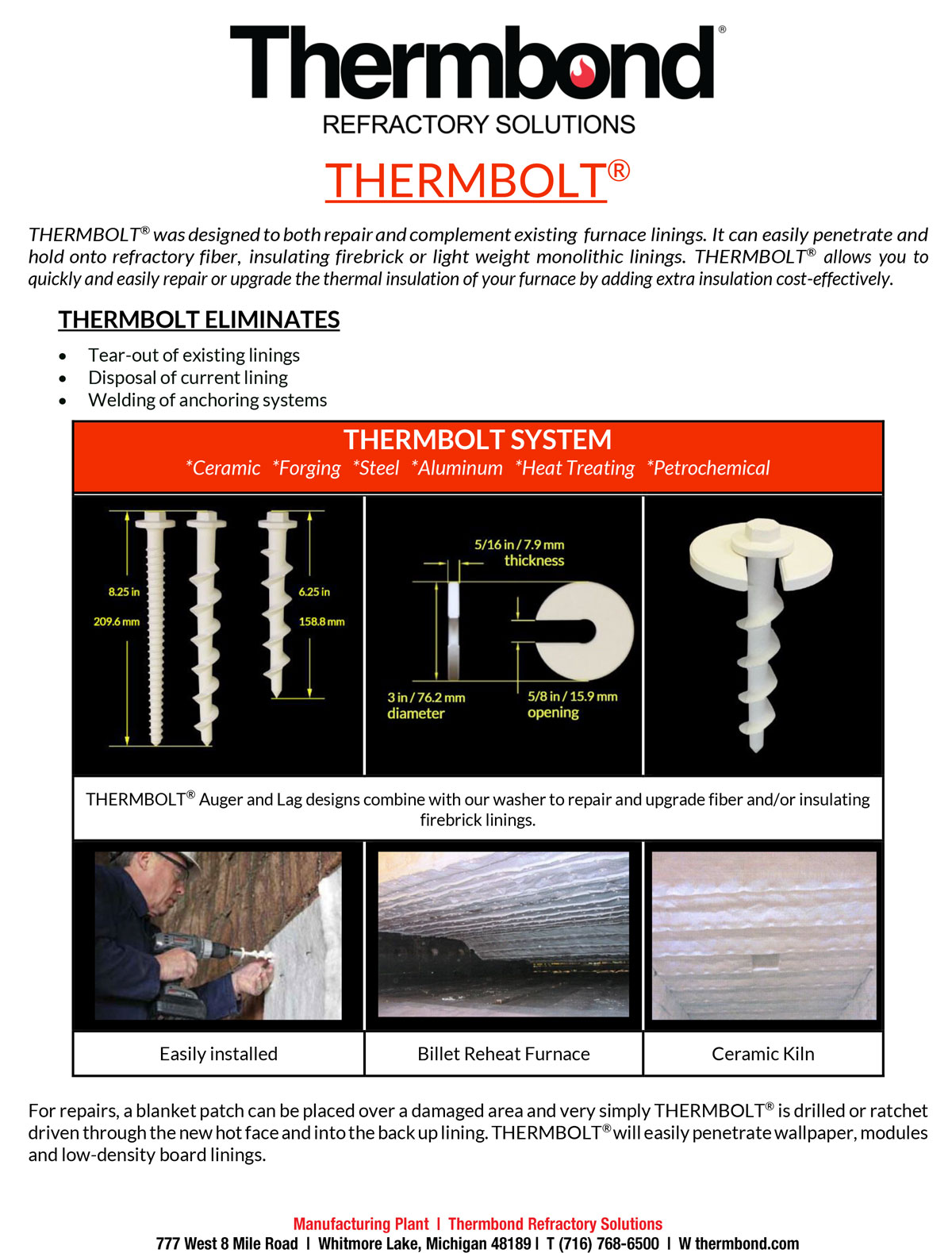

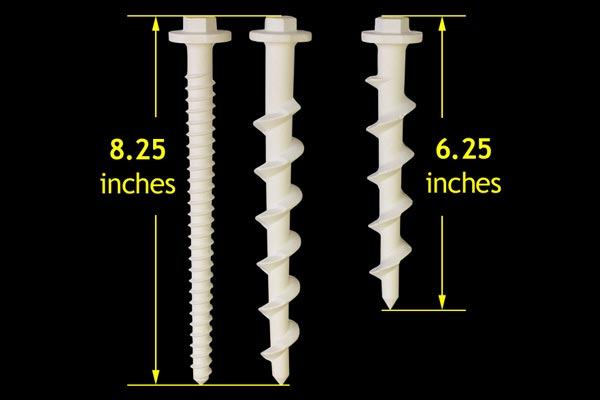

THERMBOLTS – INSTALLATION MADE EASY

THERMBOLTS – INSTALLATION MADE EASY

In addition to standard forms of installation, The MAFTEC™ veneering system, or “MAFTEC™ Blanket” allows for highly flexible installation options.

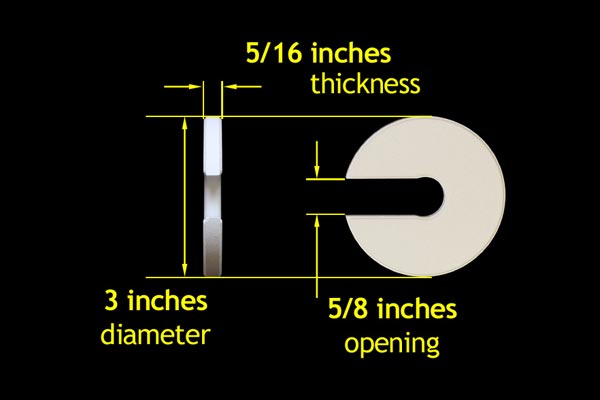

When affixed via the Thermbolt system, MAFTEC™ Blankets can be placed over deteriorated insulating brick on furnace walls/roofs without the need for tear out and disposal of the old lining, and can be secured to damaged areas with Thermbolts or ratcheted through the new hot face and into the back-up lining. No mark-outs are needed, and furnace downtime is kept to an absolute minimum.

LEARN MORE

Thermbolts